The global pet industry continues to expand as more families treat their animals like true members of the household. This shift has increased demand for custom dog toys and custom pet products that combine safety, durability, and brand identity. Businesses looking to stand out in a competitive market are turning to tailored manufacturing solutions that reflect their unique vision while meeting modern pet owner expectations.

1. Why Custom Dog Toys Are in High Demand

Pet owners today are more selective about what they buy for their dogs. They want toys that are safe, long-lasting, and suited to their pet’s size and behavior. Custom dog toys allow brands to create products designed for specific chewing strengths, breed sizes, and play styles.

Instead of selling generic items, companies can offer:

- Breed-specific chew toys

- Interactive puzzle toys

- Training-friendly fetch toys

- Dental health toys

- Personalized plush toys

Custom production ensures every detail—from shape to texture—is optimized for real-world use.

2. The Benefits of Custom Pet Products for Growing Brands

Custom pet products go beyond toys. Businesses can develop branded bowls, feeders, grooming tools, collars, and travel accessories. When companies control design and production, they gain several advantages:

- Stronger brand identity

- Higher perceived value

- Better product differentiation

- Improved profit margins

- Greater customer loyalty

Private labeling and OEM manufacturing help retailers create exclusive collections that cannot be easily copied by competitors.

3. Materials Used in Custom Dog Toy Manufacturing

Material selection plays a crucial role in product safety and durability. Manufacturers typically use:

Natural Rubber

Strong, flexible, and safe for chewing. Ideal for aggressive chewers.

TPR (Thermoplastic Rubber)

Durable yet softer than natural rubber. Suitable for interactive toys.

Silicone

Food-grade silicone is safe, flexible, and easy to clean. Perfect for treat-dispensing toys.

Plush Fabric

Used for comfort toys and light chewers. Often combined with reinforced stitching.

Choosing the right material ensures that custom dog toys meet international safety standards and satisfy pet owners.

4. Designing Custom Dog Toys for Different Chewing Levels

Not all dogs chew the same way. Customization allows brands to design toys for:

- Light chewers (puppies and small breeds)

- Moderate chewers

- Aggressive chewers

For aggressive chewers, thicker rubber walls and reinforced cores prevent quick destruction. For puppies, softer materials protect developing teeth. This tailored approach increases product longevity and customer satisfaction.

5. Custom Shapes and Branding Opportunities

One major advantage of custom dog toys is complete control over design. Businesses can create unique shapes that align with their branding—bones, animals, food shapes, or abstract designs.

Customization options include:

- Embossed logos

- Printed brand names

- Custom colors

- Packaging with brand identity

- QR codes for digital engagement

Strong branding on custom pet products builds recognition and trust in crowded marketplaces.

-

Safety Standards for Custom Pet Products

Safety is non-negotiable in the pet industry. Reputable manufacturers ensure products comply with regulations such as:

- Non-toxic material testing

- BPA-free certifications

- Phthalate-free standards

- Durability and bite resistance testing

Quality control inspections during production prevent defects and ensure every batch meets expectations. Clear safety certifications increase consumer confidence and reduce liability risks.

7. Eco-Friendly Custom Dog Toys

Sustainability is becoming an important factor in purchasing decisions. Many brands now request eco-conscious materials for their custom dog toys.

Options include:

- Natural rubber from renewable sources

- Recycled fabric stuffing

- Biodegradable packaging

- Minimal plastic wrapping

Eco-friendly custom pet products appeal to environmentally aware consumers and enhance brand reputation.

8. Manufacturing Processes for Custom Pet Products

Professional manufacturers use various production methods depending on the product type:

Injection Molding

Ideal for rubber and silicone dog toys. Provides consistent shapes and high-volume output.

Compression Molding

Used for thicker rubber items with strong durability requirements.

Sewing and Stitching

Applied in plush toy production with reinforced seams for extended lifespan.

Advanced production techniques ensure accuracy, efficiency, and consistent quality across large orders.

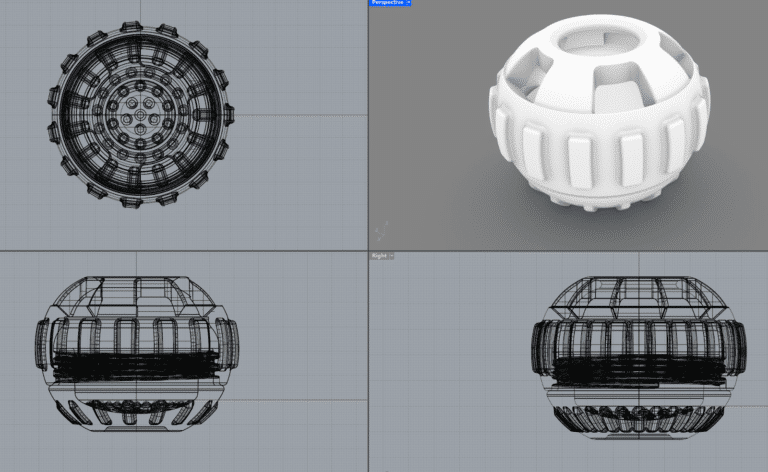

9. The Role of Prototyping in Custom Dog Toy Development

Before mass production begins, prototypes are created for evaluation. This stage allows brands to:

- Test durability

- Evaluate design appearance

- Assess chew resistance

- Make adjustments

Prototyping reduces production risks and ensures the final product meets expectations. It also allows businesses to test samples with real pets before launching to the market.

-

Trends Shaping the Future of Custom Dog Toys

Several trends are influencing product development:

- Interactive treat-dispensing toys

- Slow-feeder toy combinations

- Durable rope and rubber hybrids

- Personalized name-engraved toys

- Multi-functional travel-friendly toys

Brands that respond to changing consumer preferences are more likely to maintain steady growth.

-

Why Custom Pet Products Create Competitive Advantage

In a market filled with mass-produced items, custom pet products offer uniqueness. Exclusive designs prevent direct price competition and strengthen brand recognition. Customers are more likely to return when they associate high quality and durability with a specific brand.

Custom dog toys allow businesses to control every detail—from material selection to packaging—resulting in better margins and stronger market positioning.

Conclusion:

Custom dog toys and custom pet products are more than just merchandise—they represent brand identity, quality commitment, and long-term business strategy. With tailored designs, durable materials, and reliable manufacturing partners, businesses can meet rising consumer expectations while standing out in a crowded pet market.

As demand for premium and personalized pet accessories continues to grow, companies that invest in custom production solutions are well-positioned for lasting success.